We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

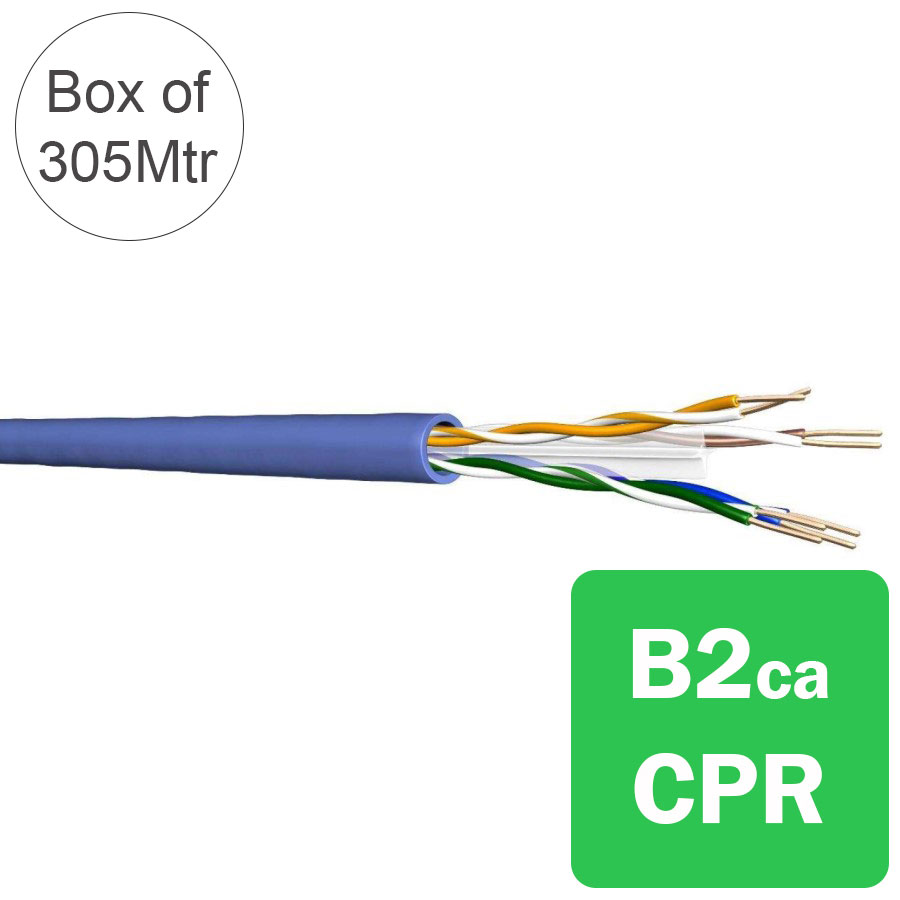

Fibre Data Cabling Supplies, Equipment & Accessories

Your one-stop shop for telecom & broadband solutions

From the network core to service delivery edge, Netceed offers a wide range of tailored products, materials, and solutions supported by our global team of service delivery experts.

The Future of Communications, Delivered Today

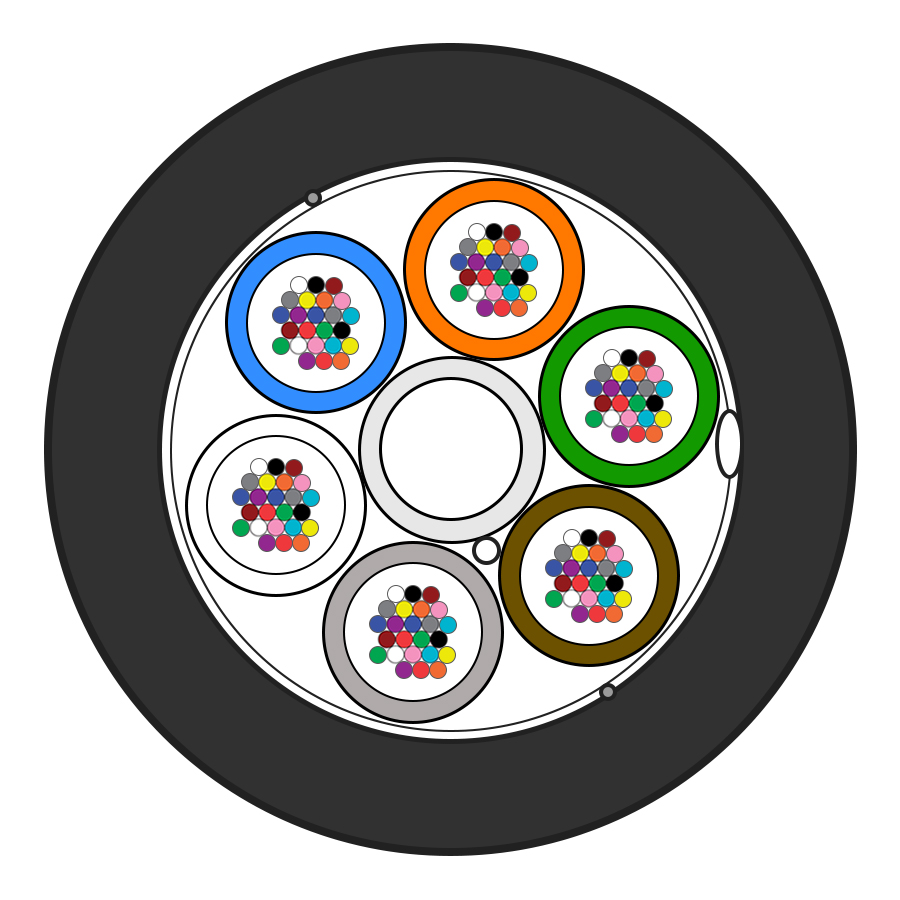

Intelligent Distribution

We're committed to providing streamlined delivery of our comprehensive portfolio of network components and expert product selection for smarter network solutions.

Value-Added Services & Solutions

We’re redefining what a value-added services provider can be and do for our customers with best-in-class supply chain and logistics capabilities.

Research & Development Lab

We design and manufacture customised products from our specialised telecom engineering team.

We're committed to providing streamlined delivery of our comprehensive portfolio of network components and expert product selection for smart network solutions.